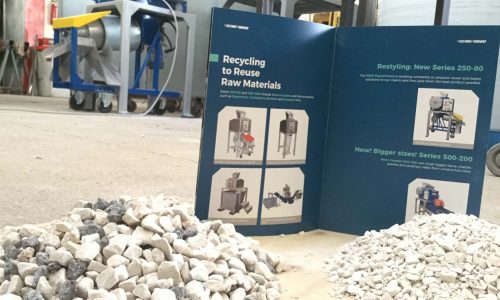

Standard Crusher

500-200

- Overall dimensions: 1180 x 980 x 2150h mm

- Total Weight: 1060 Kg

- Motor power: 5,5kW – 380/400V – 50/60Hz

- Max Output (capacity): 4 – 5 m³/ hr

- Loading Hopper: 500 x 500 mm

- Crusher Opening (max): 500 x 190 mm

1° scrollbar: 500 x 130 mmNEW

2° scrollbar: 500 x 190 mmNEW - Mobil Plate Level: 9 adjustments (each scroollbar)

- Size Output Separated:

1° scrollbar opening chamber → 0 – 40 mm

2° scrollbar opening chamber → 0 – 60/80 mm

Benefits

The 500-200 Model is the basic version of the Crusher, to which you can add the desired accessories, according on your personal processing needs. This version, compared to the 250-80 model, has a double blades’ adjustment system, double scrollbar opening chamber and nine adjustments on each scrollbar, thus allowing to recycle and reduce both waste and stones’ raw materials

Assemble our machine

Crusher and by 4-output Separation System

500-200 M4

- Overall dimensions: 1100 x 2750 x 2100h mm

- Total Weight : 1480 Kg

- Motor power: 7,5kW – 380/400V – 50/60Hz

- Max Output (capacity): 4 – 5 m³/ hr

- Loading Hopper: 500 x 500 mm

- Crusher Opening (max): 500 x 190 mm

1° scrollbar: 500 x 130 mmNEW

2° scrollbar: 500 x 190 mmNEW - Mobil Plate Level: 9 adjustments [each scrollbar]

- Size Output:

1° scrollbar opening chamber → 0 – 30/40 mm

2° scrollbar opening chamber → 0 – 60/80 mm - Size Output Separated (mm) : 4 output (customized)

Integrated automatic crusher with separator and conveyor belts

500-200M4 2-PLUSX

- Dimensions: 5500 x 2000 x 2400h mm Total

- Weight: 1650 kg

- Electrical power: 9.5 kW – 380/400V – 50/60Hz

- Productivity: 4 – 5 m³/hr

- Loading hopper: 500 x 500 mm Crushing

- Chamber: 500 x 190 mm

1st track: 500 x 130 mm

2nd track: 500 x 190 mm - Jaw adjustment: 9 levels [for each track]

- Output:

1st track → 0 – 30/40 mm

2nd track → 0 – 60/80 mm - Screening (mm): 4 Separations (customizable)

PLUS Conveyor Belts

- Footprint size: 3000/5000 x 550 mm (height: adjustable)

- Loading hopper: 650 mm

- Belt width: 350 mm

- Belt thickness: 15 mm

- Electrical power: 0.75/1.50 kW – 380/400V – 50/60Hz

Accessories

Separation System M3

Permits the selection of the output in three customized parts

Tipping container C1

Useful for collecting materials, with superior grip

Tipping container C2

Useful for collecting materials,

with lower fork grips

Detection sensor X

Useful for conveyor belts’ automatic management

Conveyor belt PLUS

Ideal to transfer materials both at the inlet (crusher) and at the outlet (container).

Lateral Staircase K

Facilitates manual insertion of the material

Related Product

Media and Project